Praised by German Engineers! V&T Assists Dongguan Bock in Energy-Saving Retrofit of Die Casting Machines, Proven to Save 45%-60% Energy Over Two Years.

The V&T asynchronous servo system has successfully enabled Bock (Dongguan) to complete an energy-saving retrofit of its die casting machines.

Following project submission, Germany-based BOCK Group conducted a rigorous nine-month validation process before proceeding with a comprehensive retrofit of its 800T–1000T die casting machines. After an on-site inspection, German engineers were highly impressed by the energy-saving performance and even made a special visit to V&T’s booth at an industry exhibition to commend the technology.

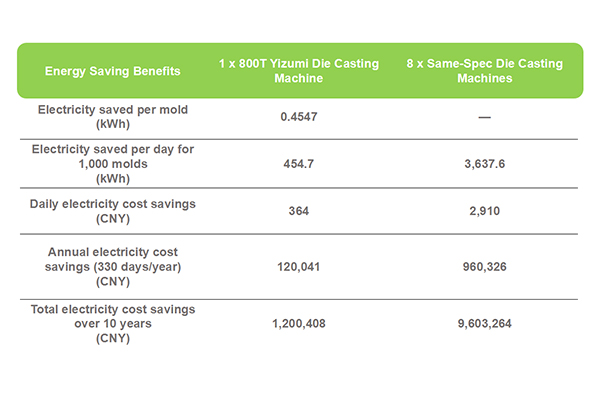

In the table, the first row shows pre-retrofit data: 0.7058 kWh per mold.The second row shows post-retrofit data in energy-saving mode: 0.2511 kWh per mold, saving 0.4547 kWh per mold.

Based on 1,000 molds per day, 330 operating days per year, and an average electricity rate of CNY 0.8/kWh, the energy-saving benefits are calculated as follows:

After more than two years of real-world operation, the system has demonstrated significant advantages:

Derechos de autor © 2026 Shenzhen V&T Technologies Co.,Ltd.. Reservados todos los derechos. Poder por

Red IPv6 admitida